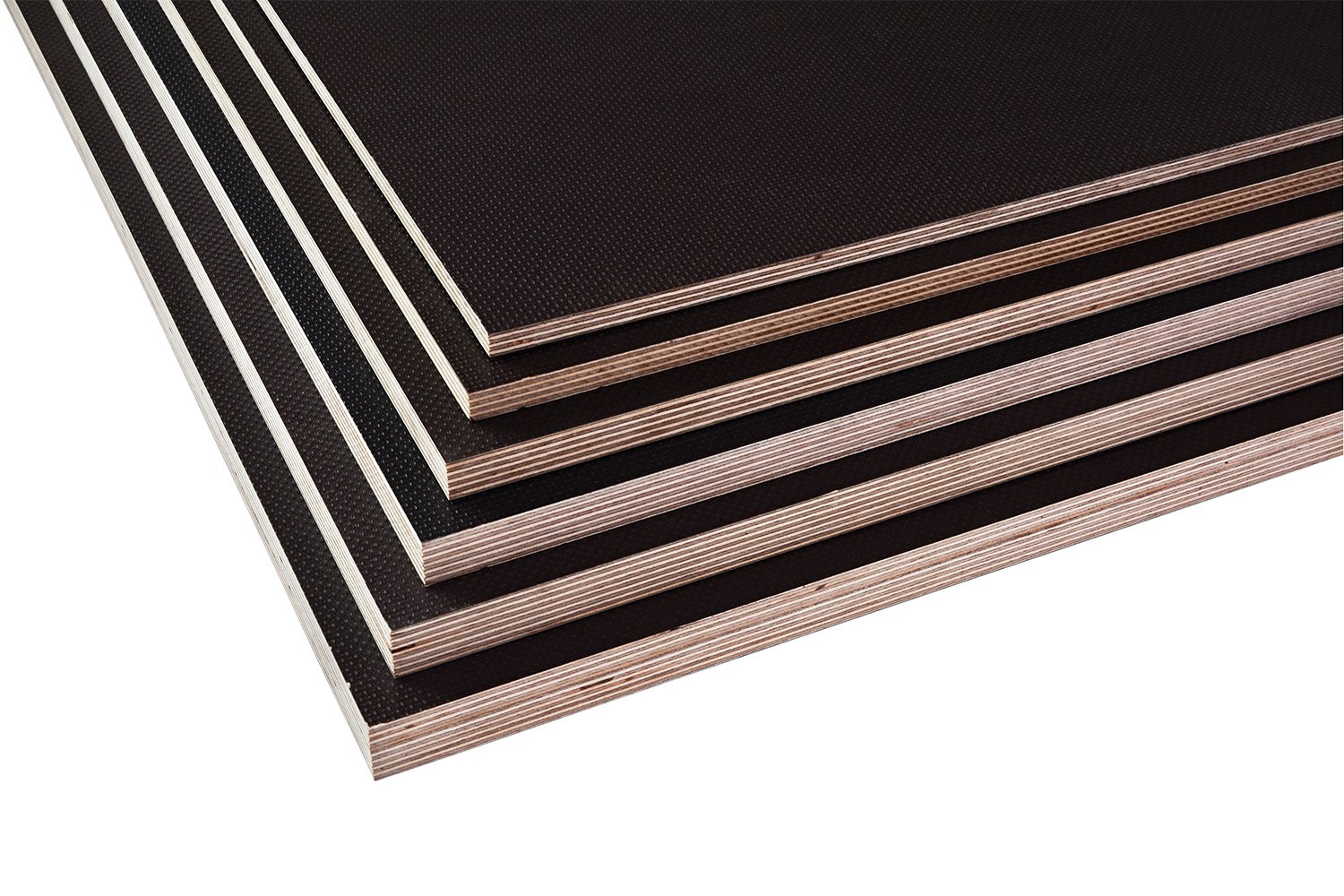

| Surface type | Anti-slip, 120g/m2, Dark Brown |

| Thickness (mm) | 9-27 |

| Dimensions (mm) | 1220x2440x1220 (4x8x4), 1250x2500x1250 (4x8x4) |

| Number of layers | 5-19 |

| Degree | I/I, I/II |

| Moisture content | 10 % +/- 2% |

| Glue content | Phenol-formaldehyde (WBP), E1 |

| Veneer thickness | 1.5 mm |

| Production standard | EN 636-3S |

Our Birch plywood is sourced from the Baltic countries, where production is meticulously monitored to ensure high quality.

Ideal for applications requiring high resistance to wear and less slippery surfaces, including:

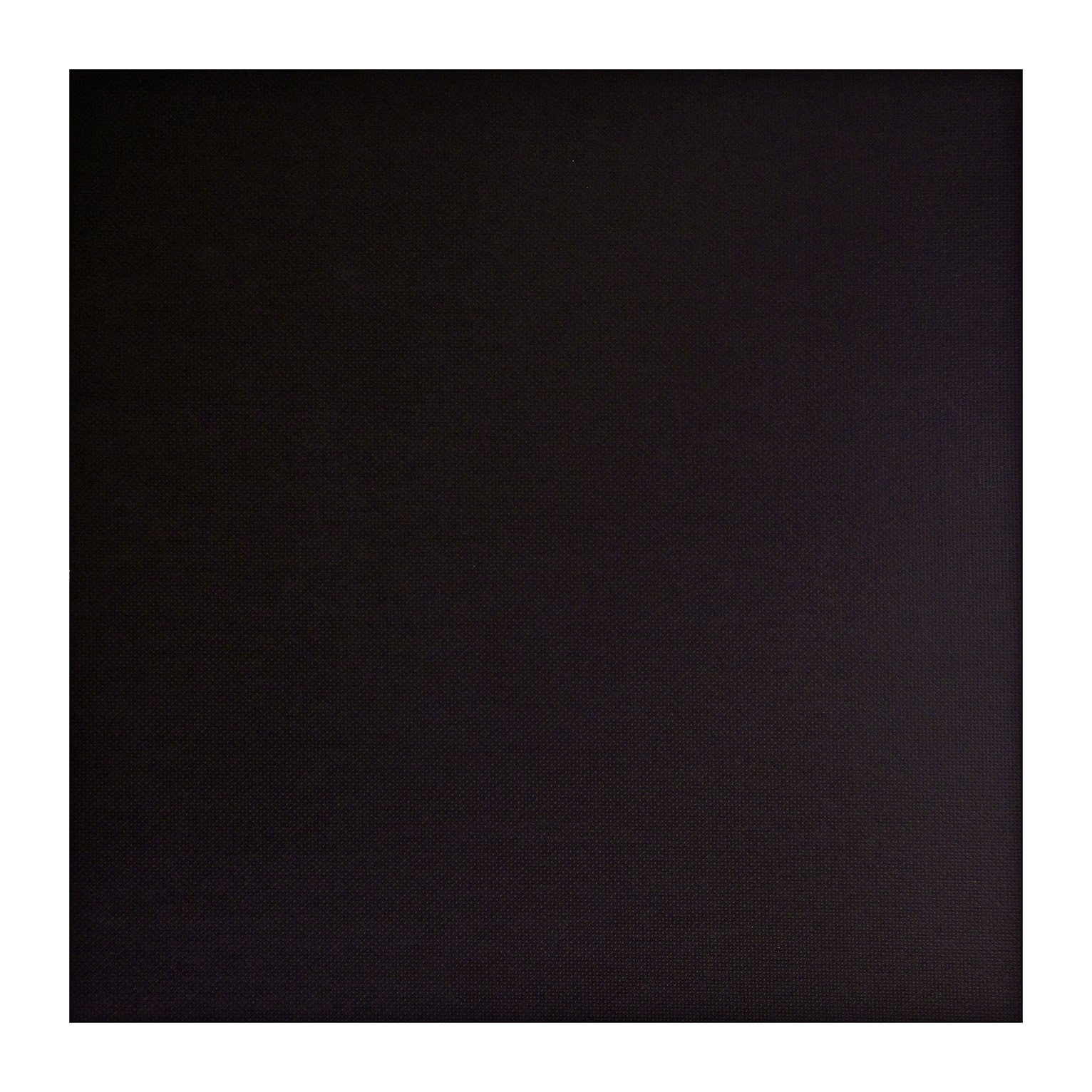

High-quality 100% birch plywood with a 120-240 g/m² film on both faces. One face is smooth (F), and the other has a rough wire mesh pattern (W). Laminated plywood is made using a plate and hot-pressing the pattern onto the film surface. It provides maximum slip resistance and is resistant to wear. Waterproof glue is used in the production of plywood, and its edges are treated with waterproof paint to protect against deformation and ensure resistance to diverse climatic conditions, including humidity and UV exposure, as well as exposure to chemicals. The surface is easy to clean and environmentally friendly.

Suitable for platforms, stage systems, and vehicle and trailer floors.

Our Birch plywood is produced with 100 % Birch, ensuring the highest quality and performance.

Birch Wire mesh plywood

| Thickness (mm) | Well of layers | Size (mm) | pcs/pallet |

| 9 | 7 | 1220x2500 | 67 |

| 12 | 9 | 1220x2500 | 50 |

| 15 | 11 | 1220x2500 | 40 |

| 18 | 13 | 1220x2500 | 33 |

| 21 | 15 | 1220x2500 | 29 |

| 24 | 17 | 1220x2500 | 25 |

| 27 | 19 | 1220x2500 | 22 |